Electroless Nickel Composite Plating Services

Electroless Nickel - TWINCLAD® XT COMPOSITE COATING

Twin City Plating (TCP) has been working closely with its suppliers over the years to develop different composite EN coatings to provide customers with alternatives – helping to reduce costs, and increase their capabilities. Give us a call and we can discuss the specifics of the different options, to help find the best solution for your application..

The Challenge: Develop an electroless nickel (EN) deposit that exceeds the release and wear characteristics of conventional EN composite coatings.

The Solution: TwinClad® XT chemistry is formulated to deliver a low coefficient of friction and special performance characteristics ideal for injection mold applications including glass-filled resins and silicone rubber.

Twin City Plating (TCP) has been working closely with its suppliers over the years to develop different composite EN coatings to provide customers with alternatives – helping to reduce costs, and increase their capabilities. Give us a call and we can discuss the specifics of the different options, to help find the best solution for your application..

The Challenge: Develop an electroless nickel (EN) deposit that exceeds the release and wear characteristics of conventional EN composite coatings.

The Solution: TwinClad® XT chemistry is formulated to deliver a low coefficient of friction and special performance characteristics ideal for injection mold applications including glass-filled resins and silicone rubber.

Twin Clad® XT Composite Plating

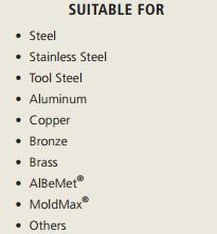

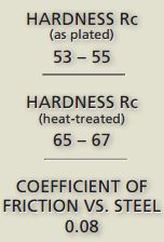

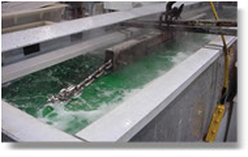

TwinClad XT is a proprietary formulation that was introduced to achieve a hard electroless nickel coating with a low coefficient of friction. The demand originated from the plastic injection mold industry to help solve poor part release issues and constant wear on their molds. However it has grown to solve countless issues in many different industries. The coating is a midphos. electroless nickel bath with boron nitride particles co-deposited into the nickel coating. The co-deposition of the particles helps keep the coating lubricious even as the coating slowly wears over time. Compared to your common post plating applications of lubricious materials that quickly wear away and need to be reapplied time and time again. Another composite EN coating is EN with co-deposited PTFE. TCP is capable of setting this bath up, but what we have found is that most customers prefer the boron nitride particles. This is due to that fact they can withstand higher temperatures then the PTFE particles, have a lower coefficient of friction and are a harder particle. Thus creating a harder and more lubricious coating all together. TwinClad XT has been used in the fire arms industry as a replacement for Nickel Boron due to it's lubricious properties. Feel free to request a quote or ask us about your application to see if TwinClad XT is the right choice.

TwinClad XT is a proprietary formulation that was introduced to achieve a hard electroless nickel coating with a low coefficient of friction. The demand originated from the plastic injection mold industry to help solve poor part release issues and constant wear on their molds. However it has grown to solve countless issues in many different industries. The coating is a midphos. electroless nickel bath with boron nitride particles co-deposited into the nickel coating. The co-deposition of the particles helps keep the coating lubricious even as the coating slowly wears over time. Compared to your common post plating applications of lubricious materials that quickly wear away and need to be reapplied time and time again. Another composite EN coating is EN with co-deposited PTFE. TCP is capable of setting this bath up, but what we have found is that most customers prefer the boron nitride particles. This is due to that fact they can withstand higher temperatures then the PTFE particles, have a lower coefficient of friction and are a harder particle. Thus creating a harder and more lubricious coating all together. TwinClad XT has been used in the fire arms industry as a replacement for Nickel Boron due to it's lubricious properties. Feel free to request a quote or ask us about your application to see if TwinClad XT is the right choice.

Innovative Customer Tailored Metal Finishing Solutions

|

Uniformity Twin City Plating chemistry and process control guarantee accuracy to tolerances of 0.0001 inch. Wear Resistance Superior hardness and pore-free deposit qualities increase resistance to abrasion and adhesive wear for longer coating life. Specialized Formulation The unique coating provides significantly better wear and release properties without compromising hardness which makes TwinClad® XT ideal in the most challenging applications from glass-filled resins to silicone rubber. Environment Sensitive to environmental concerns, Electroless Nickel and the associated composites help to minimize waste and the impact on the environment. Maintenance Can be easily stripped and replated to replenish wear and release properties and maintain optimum production levels. Quick Release The lubricious coating provides an exceptionally low coefficient of friction for the high productivity of snag-free production and longrunning wear. Corrosion Resistance An undercoat of High Phosphorus EN will improve the corrosion resistance capabilities of the TwinClad® XT - protecting the base material.

| |||||||

Other Electroless Nickel Composites

Electroless Nickel (EN) composites have been used for many different purposes for a number of years. Given EN’s amorphous structure, polymers and other non-conducting materials can be co-deposited providing capabilities above and beyond traditional EN. Teflon, Carbide, Diamond, Boron-Nitride – can all be used to improve the characteristics of the coating – Hardness, Lubricity, Corrosion Resistance, Abrasion Resistance, etc.

Silicon Carbide Composites

When your parts are in a highly abrasive environment with little or no lubrication Electroless nickel with co-deposited silicon carbide particles is what you want. Used in many different industries, but quite popular in the oil & gas industry it can drastically increase the wear life of your parts. Upon request TCP can setup to run a Silicon Carbide EN bath. Call or email for more information.

Diamond Composites

Sounds expensive, but it’s not as bad as you think. This patented bath consists of tiny diamond particles (dust) that is introduced into the electroless nickel bath and deposited as the nickel is deposited to the part. Particle size can vary from nanometers to 8 microns and will be determined case by case. Diamond composite EN coatings will be significantly harder and more wear resistant than hard chrome and even silicon carbide composite EN. Upon request TCP can setup to run a Diamond Composite EN bath. Call or email for more information.

Electroless Nickel (EN) composites have been used for many different purposes for a number of years. Given EN’s amorphous structure, polymers and other non-conducting materials can be co-deposited providing capabilities above and beyond traditional EN. Teflon, Carbide, Diamond, Boron-Nitride – can all be used to improve the characteristics of the coating – Hardness, Lubricity, Corrosion Resistance, Abrasion Resistance, etc.

Silicon Carbide Composites

When your parts are in a highly abrasive environment with little or no lubrication Electroless nickel with co-deposited silicon carbide particles is what you want. Used in many different industries, but quite popular in the oil & gas industry it can drastically increase the wear life of your parts. Upon request TCP can setup to run a Silicon Carbide EN bath. Call or email for more information.

Diamond Composites

Sounds expensive, but it’s not as bad as you think. This patented bath consists of tiny diamond particles (dust) that is introduced into the electroless nickel bath and deposited as the nickel is deposited to the part. Particle size can vary from nanometers to 8 microns and will be determined case by case. Diamond composite EN coatings will be significantly harder and more wear resistant than hard chrome and even silicon carbide composite EN. Upon request TCP can setup to run a Diamond Composite EN bath. Call or email for more information.

Articles

| Two-Body Abrasive Wear of EN Composite Coatings - Twin Clad XT | |

| File Size: | 3493 kb |

| File Type: | |

| Comparison of Electroless Vs. Electrolytic Nickel Deposits | |

| File Size: | 423 kb |

| File Type: | |

| Use of EN & Composite for Mold & Die Applications | |

| File Size: | 1598 kb |

| File Type: | |

| The Effect of Electroplating on Thread Dimension | |

| File Size: | 304 kb |

| File Type: | |