Anodize, Hard Coat Anodize & Chem Film Services

Anodize | MIL-A-8625 Type II

Class I Clear

Class II Dyed – black

Anodize (Type II) is an electrolytic process used to increase the thickness of the natural Aluminum oxide layer of Aluminum parts and components. By increasing the oxide layer, the corrosion resistance and wear resistance of the processed parts is increased. Anodize also provides for better adhesion of paints and primers to Aluminum surfaces as compared to bare metal. Typical thickness .0002-.0004”, dyed .0006-.0008”.

Hard Coat Anodize | MIL-A-8625 Type III

Class I

Class II Dyed – black

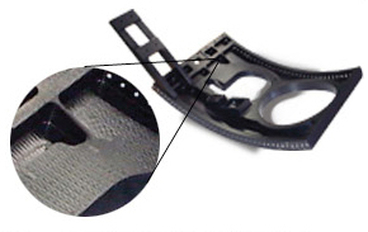

Hard Coat Anodize (Type III) is similar to Anodize in that it increases the thickness of the natural Aluminum oxide layer, though Hard Coat Anodize is a much thicker and harder coating - .001-.002” thick and up to 70 Rc. Parts and components that have been Hard Coat Anodized can be impregnated with Teflon (PTFE) after processing reducing the coefficient of friction. TCP runs a traditional 32°F chilled Hard Coat bath, which has been proven to produce a harder aluminum oxide layer than an oxide layer produced in room temperature Hard Coat bath.

Tank Size: Anodizing/Hard Coat Anodize |Clear & Black Color

36” wide x 96” long x 48” deep - 2000 lb. Hoist

Class I Clear

Class II Dyed – black

Anodize (Type II) is an electrolytic process used to increase the thickness of the natural Aluminum oxide layer of Aluminum parts and components. By increasing the oxide layer, the corrosion resistance and wear resistance of the processed parts is increased. Anodize also provides for better adhesion of paints and primers to Aluminum surfaces as compared to bare metal. Typical thickness .0002-.0004”, dyed .0006-.0008”.

Hard Coat Anodize | MIL-A-8625 Type III

Class I

Class II Dyed – black

Hard Coat Anodize (Type III) is similar to Anodize in that it increases the thickness of the natural Aluminum oxide layer, though Hard Coat Anodize is a much thicker and harder coating - .001-.002” thick and up to 70 Rc. Parts and components that have been Hard Coat Anodized can be impregnated with Teflon (PTFE) after processing reducing the coefficient of friction. TCP runs a traditional 32°F chilled Hard Coat bath, which has been proven to produce a harder aluminum oxide layer than an oxide layer produced in room temperature Hard Coat bath.

Tank Size: Anodizing/Hard Coat Anodize |Clear & Black Color

36” wide x 96” long x 48” deep - 2000 lb. Hoist

|

Chemical Conversion Coating | MIL-DTL-5541

Twin City Plating is now featuring a RoHS compliant, hex-chromium free Chemical Conversion Coating (Chromate Conversion, or Chem Film) coating that meets MIL-C-5541 and EU ELV directive requirements and is QLP approved. The TCP-HF Chromate Conversion coating originally developed by the United States Navy for extreme conditions. Without any topcoat or sealer TCP-HF out performs many other RoHS compliant conversion coatings on the market in corrosion resistance, durability, as well as with paint and adhesive bonding. The TCP-HF can also be used as an Anodize and Hard Coat Anodize sealer for improved corrosion resistance capabilities. For more information on capacity and pricing please contact us. Tank Size: Chem Conversion 48"long x 17"wide x 47"tall |

Innovative Customer Tailored Metal Finishing Solutions

Follow the Link to See More of Our Finishing Services